Introduction – Exploring China’s Reputation for Quality Injection Blow Molding Machine

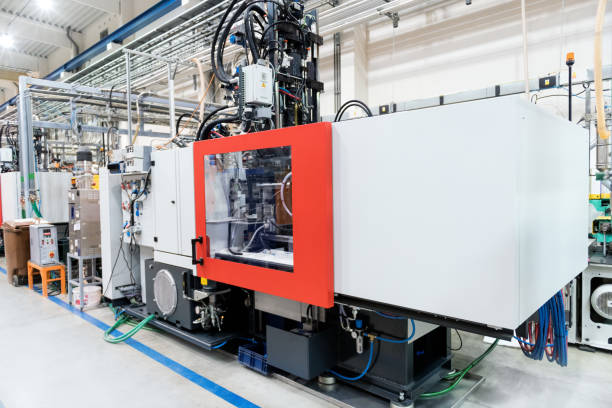

When it comes to sourcing top-tier Injection Blow Molding Machines, China is undeniably a global powerhouse. But why does China dominate this space so effectively? It comes down to a winning mix of advanced tech, skilled labor, cost efficiency, and unmatched flexibility.

Over the past few decades, Chinese manufacturers have made giant leaps in automation and robotics, resulting in machines that are precise, energy-efficient, and capable of handling complex designs. Add to that the country’s engineering talent pool, and you’ve got a recipe for reliability and innovation.

From automotive components to pharmaceutical containers, Chinese-made injection blow molding machines are used across industries. And let’s not forget the value proposition—high quality at competitive prices, thanks to efficient supply chains and lower labor costs. Whether you’re building prototypes or scaling full production, China’s manufacturing ecosystem is built to deliver.

And if you’re sourcing smartly, platforms like Freshdi give you access to verified suppliers, market insights, RFQ trends, and quality assurance tools to make informed decisions. Let’s dive deeper into what makes a great injection blow molding machine and how you can spot the best suppliers in 2025.

Defining & Verifying Injection Blow Molding Machine Excellence in China

Not all injection blow molding machines are created equal. So how do you separate the best from the rest?

Start with the quality benchmarks. A high-quality machine should offer:

- High precision and repeatability

- Energy efficiency

- User-friendly interface

- Durability and low maintenance

- Multi-cavity capability for larger production

Next, check for certifications. Look for international standards such as:

- ISO 9001: Quality Management Systems

- CE Certification: Compliance with EU safety standards

- SGS/BV Certifications: Third-party inspection reports

- UL and FDA Compliance (for medical-grade production)

It’s also worth noting that regional variations across China impact manufacturing quality. For example, Guangdong is known for tech-focused production, while Zhejiang and Jiangsu are hubs for precision engineering.

If you’re unsure about a supplier’s credibility, platforms like Freshdi let buyers post RFQs (Request for Quotation) that specify certification requirements. You can also view past transaction data, buyer reviews, and verified product specs.

Top 6 Verified Injection Blow Molding Machine Suppliers in China – Leaders in Quality

Sourcing from the right supplier can make or break your production line. Based on performance, export volume, and verified buyer feedback on Freshdi, here are the top 6 Injection Blow Molding Machine suppliers in China for July 2025:

-

Taizhou Enji Mold Plastic Technology Co., Ltd.

Specializes in PET preform machines and multi-use blow molding systems. Known for fast lead times and strong after-sales support. -

Zhangjiagang Proman Machine Co., Ltd.

Offers a wide range of servo-driven machines for food and beverage packaging. Highly rated for machine efficiency and customization. -

GUANGZHOU JASU PRECISION MACHINERY CO., LTD

Excels in small-scale, precision machines ideal for pharmaceutical and cosmetic packaging. -

Zhangjiagang Sunswell Machinery Co., Ltd.

Focuses on high-speed, fully automated systems. Great for large-scale production of water and juice bottles. -

Nanjing Likesmile New Energy Technology Co., Ltd.

Specializes in foam injection systems, especially for automotive applications. -

Guangzhou Jasu Machine Co., Ltd.

Offers one-stage injection blow molding machines, perfect for pharmacy and sanitizer containers.

Dynamic Ranking Note

It’s worth mentioning that platforms like Freshdi feature dynamic rankings such as “Supplier of the Month” or “Supplier of the Quarter.” These rankings reflect real-time performance, buyer feedback, and innovation metrics—so be sure to check Freshdi’s updated lists regularly to spot rising stars or high-performing suppliers.

Market Navigation – Trends in Quality Demand & Global Consumer Preferences

The injection blow molding machine market isn’t what it used to be. It’s evolving—and fast.

Rising Demand for Premium Machines

China’s injection molding machine market hit USD 4.48 billion in 2023, and it’s projected to reach USD 6.01 billion by 2030. Industries like toys, automotive, packaging, and medical devices are fueling this growth. Buyers now prefer premium, certified machines that offer longevity, precision, and scalability.

Technology Trends Shaping the Market

Today’s machines are smarter. Features like IoT integration, AI-based monitoring, and real-time data tracking are becoming standard. Electric and hybrid models are also gaining traction due to their energy efficiency and environmental benefits.

Eco-Conscious Consumer Demands

Sustainability is no longer optional. Brands are under pressure to reduce carbon footprints, and that means using eco-friendly machines that can work with biodegradable materials or recycled plastics.

Customization & Small-Batch Production

Consumers now want unique, personalized products. That’s driving demand for machines capable of quick mold changes and short production runs—especially in the electronics and beauty sectors.

Traceability & Compliance

Governments and consumers both demand transparency. Machines that offer real-time tracking, batch reporting, and regulatory compliance are in high demand—especially for medical, food-grade, and children’s products.

Platforms like Freshdi help buyers identify suppliers that meet these evolving standards, offering filters and RFQ options tailored to traceability, sustainability, and tech integration.

Conclusion – Sourcing Quality Injection Blow Molding Machine Strategically

China continues to set the bar high in the injection blow molding machine industry—with its blend of innovation, cost-efficiency, and production flexibility. But sourcing the right machine isn’t just about price—it’s about quality, compliance, and future-readiness.

Here’s a quick checklist for businesses looking to source smartly:

- ✅ Prioritize machines with international certifications (ISO, CE, SGS).

- ✅ Confirm supplier credibility through platforms like Freshdi.

- ✅ Match machine features to your product needs (e.g., mold size, materials).

- ✅ Ask for test runs, performance data, or virtual demos.

- ✅ Check for after-sales service, spare parts availability, and technical support.

Using Freshdi as your sourcing partner gives you access to verified quality claims, real buyer reviews, and market insights that help you stay a step ahead. Whether you’re sourcing your first machine or upgrading for scale, sourcing smart in 2025 starts with the right partner—and the right platform.

Key Takeaways

- China leads globally in injection blow molding machine manufacturing due to innovation, skilled labor, and cost-effectiveness.

- Quality verification through certifications and supplier ratings is crucial.

- Freshdi offers verified supplier listings, RFQ customization, and real-time performance tracking.

- Trends like sustainability, traceability, and customization are shaping global demand.

- Choosing the right supplier involves more than price—it’s about compliance, support, and machine capability.

Checklist for Buyers: Sourcing Smart in 2025

- ❏ Define production needs (volume, material, certification needs)

- ❏ Use Freshdi to shortlist verified, high-performing suppliers

- ❏ Check machine specs against industry standards

- ❏ Request documentation (certifications, testing data)

- ❏ Confirm logistics, delivery timelines, and warranty terms

Future Outlook

With the market expected to cross USD 12.28 billion by 2032, driven by automotive and packaging industries, the demand for high-quality, traceable, and eco-friendly injection blow molding machines will only grow stronger. As technology advances and global standards tighten, sourcing from verified suppliers through trusted platforms like Freshdi will be more crucial than ever.

How Freshdi Empowers Buyers

- 🔍 Verified supplier profiles with export history and buyer reviews

- 📑 Easy posting of RFQs with specific quality and certification filters

- 📈 Market trend data to help forecast demand and costs

- 🛠️ Access to dynamic rankings and “Supplier of the Month” insights

- 🤝 Direct communication tools to negotiate and finalize deals

FAQs

1. What is the difference between injection molding and injection blow molding?

Injection molding forms solid parts by injecting material into a mold, while injection blow molding is used to create hollow objects like bottles by injecting and then blowing the material into shape.

2. How do I verify if a Chinese supplier is legitimate?

Use platforms like Freshdi to check export history, certifications, buyer reviews, and request third-party inspections.

3. What certifications should I look for in injection blow molding machines?

Look for ISO 9001, CE, SGS, or FDA/UL compliance depending on your industry.

4. Are Chinese machines reliable for long-term production?

Absolutely. Many Chinese manufacturers produce machines with excellent durability, especially those verified through Freshdi.

5. Can I customize the injection blow molding machine to suit my product?

Yes, most suppliers offer customization for mold size, automation level, and material compatibility. Just specify your needs clearly in your RFQ on Freshdi.

References

- shop.machinemfg.com

- nextmsc.com

- 360researchreports.com

- accio.com

- victorcn.com

- gminsights.com

- globenewswire.com

- Reuters – Rural Revitalisation

- Reuters – Smart Farming

- Reuters – Farm Modernization