In the evolving landscape of modern agriculture, loose leaf lettuce has emerged as the quintessential hydroponic crop, perfectly embodying the principles of efficiency, sustainability, and continuous production that define soilless cultivation. Unlike their head-forming counterparts, loose leaf varieties offer unique advantages that align seamlessly with hydroponic growing systems, creating an agricultural synergy that maximizes both yield and resource utilization.

Understanding Loose Leaf Lettuce: The Hydroponic Champion

Loose leaf lettuce, scientifically classified as Lactuca sativa var. crispa, represents a fundamentally different approach to lettuce cultivation. Rather than forming tight, compact heads, these varieties produce individual leaves that emerge from a central crown in an open, rosette pattern. This growth characteristic creates several distinct advantages for hydroponic cultivation that traditional head lettuces simply cannot match.

The “cut and come again” harvesting method represents the cornerstone of loose leaf lettuce’s hydroponic appeal. This technique allows growers to harvest outer leaves while leaving the central growing point intact, enabling continuous production from a single plant over extended periods. Studies show that properly managed loose leaf lettuce can provide 3-5 harvest cycles from a single root system, dramatically improving space utilization and return on investment compared to single-harvest head.

Popular loose leaf varieties for hydroponic production include Green Oak Leaf, Red Sails, Lollo Rosso, and Solar Flare. Each variety brings distinct characteristics: Green Oak Leaf offers exceptional resistance to tip burn, a common issue in hydroponic systems, while Red Sails provides stunning visual appeal with its red-bronze coloration and rapid 4-week maturity. Solar Flare stands out for its fast growth and large leaf size, making it particularly suitable for commercial hydroponic operations.

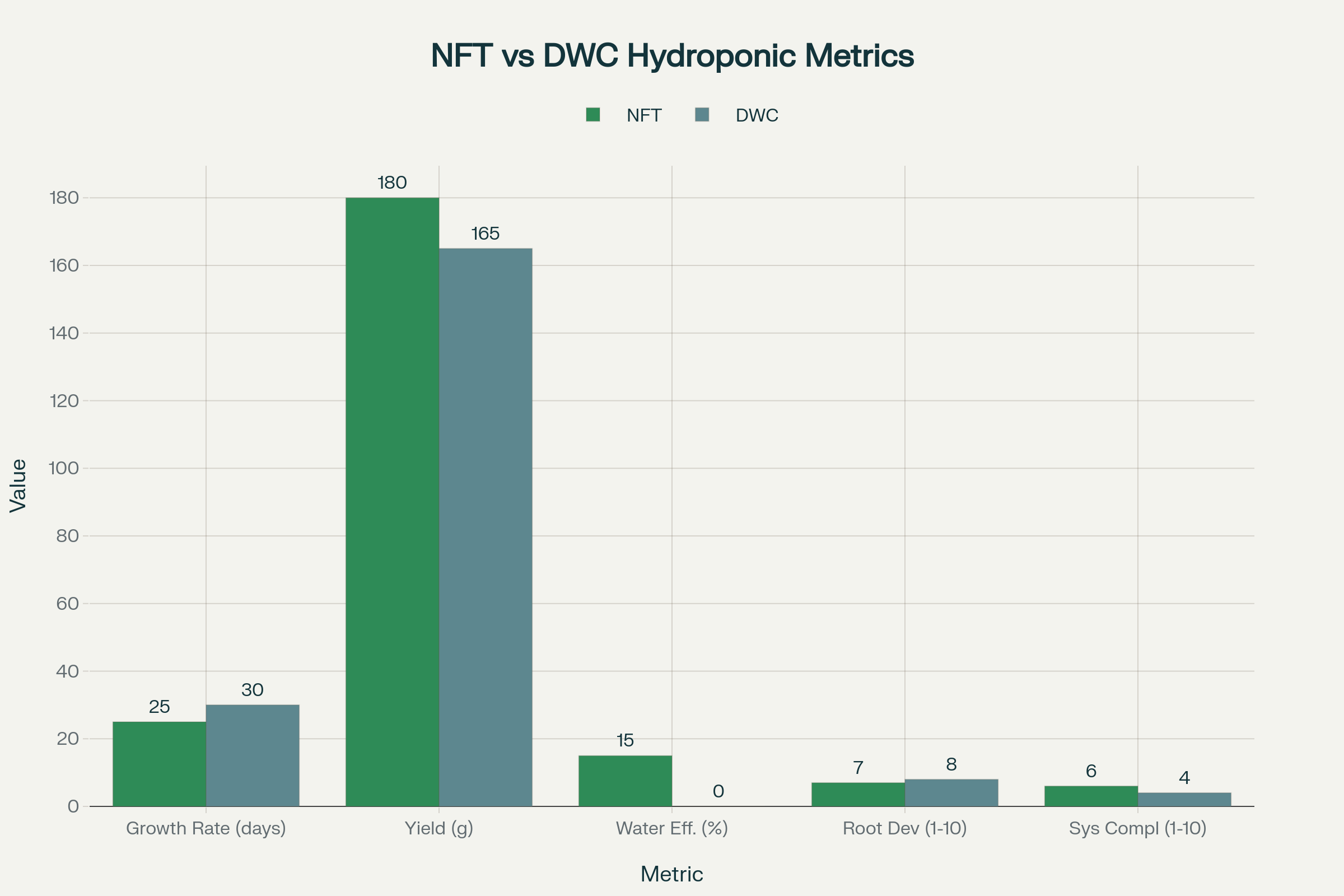

The Science of Hydroponic Systems: NFT vs. DWC Performance

The selection of appropriate hydroponic systems significantly impacts loose leaf lettuce production efficiency and quality. Research comparing Nutrient Film Technique (NFT) and Deep Water Culture (DWC) systems reveals distinct performance characteristics that influence both commercial viability and home growing success.

NFT systems demonstrate superior growth speed and yield for loose leaf lettuce, with plants reaching harvest maturity in 25 days compared to 30 days in DWC systems. This 17% reduction in growing time translates to increased annual production cycles and improved profitability. NFT-grown lettuce also shows 13-27% greater yield in various growth parameters, including leaf area, fresh weight, and dry weight.letpot+2

Water usage efficiency favors NFT systems, with 9.6% higher total water consumption that correlates with increased nutrient uptake and plant performance. While this initially suggests inefficiency, the superior growth rates and yields result in better water-to-biomass ratios. NFT systems achieve 22.8% higher fresh yield and 27.7% higher dry yield, making the increased water usage economically justified.

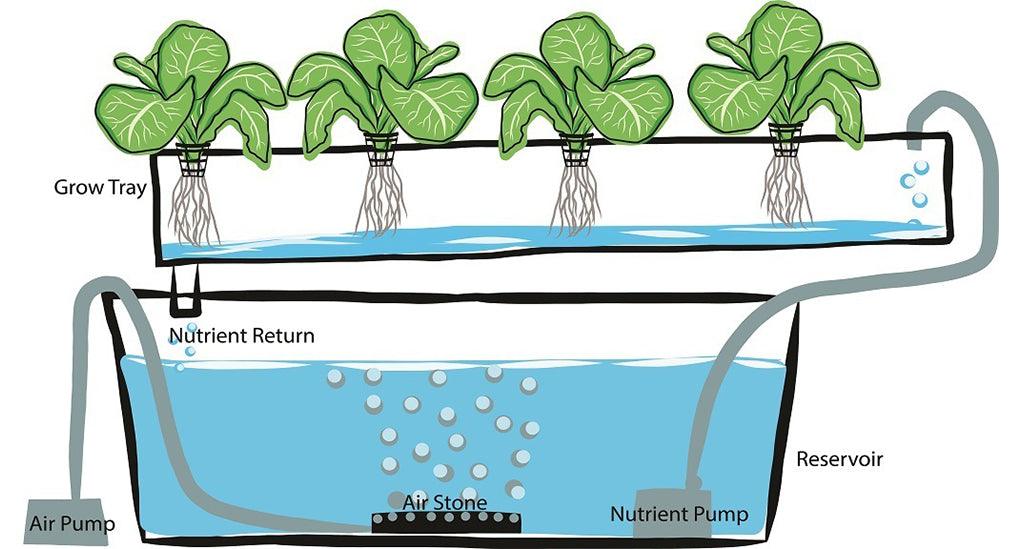

DWC systems excel in root development, providing fully submerged root environments that promote extensive root mass formation. However, this advantage must be balanced against slower overall plant development and longer harvest cycles. DWC requires continuous aeration to maintain dissolved oxygen levels, adding complexity and energy costs compared to NFT’s passive oxygenation through root exposure to air.

Performance Comparison: NFT vs DWC Systems for Loose Leaf Lettuce

Optimizing Growing Conditions for Maximum Performance

Environmental control represents a critical success factor in hydroponic loose leaf lettuce production. Optimal temperatures range from 60-70°F (15-21°C) during active growth, with germination requiring slightly warmer conditions of 70-75°F (21-24°C). Temperature stability prevents bolting, a common issue where lettuce prematurely flowers and becomes bitter.puregreensaz+1

Lighting requirements for loose leaf lettuce are moderate but precise. Plants require 12-16 hours of light daily, with 14-16 hours producing optimal growth rates. Light intensity should range from 200-400 μmol/m²/s PPFD for most varieties, though some cultivars tolerate lower light conditions better than others. LED grow lights prove most efficient for indoor production, offering precise spectral control and energy efficiency.

Nutrient management demands careful attention to pH and electrical conductivity (EC). Optimal pH ranges from 5.5-6.5, with 5.8-6.2 representing the sweet spot for nutrient uptake. EC levels should be maintained at 0.8-1.2 mS/cm during vegetative growth, increasing slightly for mature plants. Nitrogen levels require particular attention, as excessive nitrogen promotes rapid leaf growth but can reduce flavor and increase nitrate accumulation.

Advanced Cultivation Techniques and System Design

Modern hydroponic systems incorporate sophisticated design elements to maximize loose leaf lettuce production. NFT systems utilize channels with gentle slopes (1:40 to 1:80) to maintain optimal nutrient flow, ensuring all plants receive adequate nutrition without creating stagnant zones. Channel width of 4-6 inches provides adequate root space while maintaining proper nutrient film thickness.

Plant spacing optimization significantly impacts yield and quality. Loose leaf varieties can be grown at higher densities than head lettuce, with spacing of 4-6 inches between plants providing optimal balance between individual plant size and total system yield. Some commercial operations achieve even higher densities through staggered planting and selective harvesting strategies.

Substrate-based systems, including Dutch buckets and container growing, demonstrate superior performance in some metrics. Research indicates that substrate-based hydroponic systems produce 19-79% higher growth parameters compared to liquid culture systems like NFT and DWC. Substrate systems provide better root support and buffering against environmental fluctuations, though they require more initial investment and ongoing maintenance.

Harvesting Strategies for Maximum Productivity

The cut and come again harvesting method transforms loose leaf lettuce production economics. Harvesting can begin when leaves reach 4 inches in length, typically 3-4 weeks after transplanting. Three primary harvesting techniques maximize plant longevity and productivity.

Individual leaf harvesting involves selecting outer leaves while preserving the central growing point. This method provides the longest harvest period but requires more labor. Growers can harvest 2-3 leaves per plant every few days, maintaining continuous production for 8-12 weeks from a single planting.

The “ponytail” method involves gathering multiple leaves and cutting them 1-2 inches above the crown. This technique requires less labor while still preserving the plant’s ability to regrow. Recovery time averages 10-14 days between harvests, allowing 4-6 harvest cycles per plant.youtube.

Whole plant harvesting provides maximum yield per harvest but ends the plant’s productive life. This method is most appropriate when plants show signs of bolting or when space is needed for new plantings. Commercial operations often use this method for processing and packaging efficiency.

Quality Control and Food Safety Considerations

Hydroponic loose leaf lettuce production requires stringent quality control measures to ensure food safety and market acceptance. Microbial contamination represents the most significant risk, with leafy green vegetables accounting for 22% of foodborne illness outbreaks in the United States. Contamination sources include poor water quality, inadequate sanitation, and cross-contamination during harvesting and handling.

Water quality management forms the foundation of food safety protocols. Source water should meet drinking water standards, with regular testing for bacterial contamination, chemical residues, and heavy metals. Closed-loop hydroponic systems reduce contamination risks compared to open systems but require careful management to prevent pathogen buildup.

Harvest and post-harvest handling procedures significantly impact safety and quality. Workers should follow strict hygiene protocols, including hand washing, clean tools, and appropriate clothing. Harvested lettuce should be immediately cooled to 32-36°F (0-2°C) to maintain quality and extend shelf life.

Economic Advantages and Market Positioning

Hydroponic loose leaf lettuce production offers compelling economic advantages over traditional field cultivation. Yield increases of 3-5 times per square foot are common, resulting from higher plant densities, year-round production, and elimination of weather-related losses. Water usage reductions of 90-95% compared to field production significantly reduce operating costs in water-scarce regions.

Premium pricing opportunities exist for hydroponic produce, with consumers willing to pay 20-40% premiums for locally grown, pesticide-free lettuce. The “living lettuce” market segment, where plants are sold with roots intact, commands even higher prices while extending shelf life for retailers and consumers.

Energy costs represent the primary economic challenge for indoor hydroponic production. LED lighting systems, while efficient, can account for 25-30% of operating costs in fully controlled environments. Greenhouse operations reduce energy requirements while maintaining most hydroponic advantages, creating attractive economic models for many regions.

Future Innovations and Technological Integration

Emerging technologies promise to further optimize loose leaf lettuce production in hydroponic systems. Artificial intelligence and machine learning applications are being developed for automated monitoring of plant health, growth rates, and optimal harvest timing. Computer vision systems can assess leaf color, size, and quality indicators, enabling precision harvesting and quality grading.

Automation technologies are transforming both seeding and harvesting operations. Robotic systems can plant seedlings, monitor growth, and perform selective harvesting with greater consistency than manual labor. These technologies address labor shortages while improving production efficiency and reducing human error.

Controlled environment agriculture continues evolving toward complete automation and optimization. Integration of IoT sensors, automated nutrient dosing, and climate control systems creates closed-loop systems that maintain optimal growing conditions with minimal human intervention. These advances make hydroponic lettuce production accessible to a broader range of operators while improving consistency and profitability.

Conclusion: The Perfect Marriage of Crop and Technology

Loose leaf lettuce represents the ideal intersection of plant characteristics and hydroponic technology, creating production systems that maximize efficiency while minimizing resource consumption. The ability to harvest continuously from single plants, combined with rapid growth cycles and high yields, makes loose leaf varieties the cornerstone of successful hydroponic operations.

The choice between NFT and DWC systems depends on specific operational goals and constraints, with NFT systems favoring speed and water efficiency while DWC systems excel in root development and system simplicity. Both systems produce high-quality lettuce when properly managed, demonstrating the flexibility of hydroponic technology to accommodate different approaches and preferences.

As global food security challenges intensify and urbanization continues, hydroponic loose leaf lettuce production offers a scalable solution that brings fresh produce closer to consumers while reducing environmental impact. The continuous harvest nature of loose leaf varieties aligns perfectly with consumer demands for fresh, local food while providing economic viability for producers at various scales.

The future of loose leaf lettuce production lies in the continued integration of advanced technologies, sustainable practices, and optimized growing systems that deliver consistent, high-quality produce year-round. Whether in commercial greenhouses, urban vertical farms, or home hydroponic gardens, loose leaf lettuce continues to demonstrate why it remains the gold standard for hydroponic leafy green production.

About us

Try it for yourself. Freshdi.com

Global Agri B2B Marketplace.